Reciprocating Friction Tester services|high frequency friction tester : factory To facilitate the in-depth study of the tribological behavior of texture friction pairs in the process of reciprocating friction. The micro-displacement deformation output model of compliant mechanism is deduced using a new method for indirectly measuring friction coefficient through micro-deformation of double parallel four-bar compliant mechanism. Then, the whole structure . • Transport portal• Car classification• Party bus Ver mais

{plog:ftitle_list}

WEBGold Digger FRVR é um jogo emocionante que lhe dá a chance de experimentar a si mesmo no papel de um mineiro. O mineiro precisa obter joias e tipos preciosos de metais profundamente sob o solo. Seu personagem principal tem que descer a mina para que ele possa explorar as camadas do solo, onde ele pode encontrar a fonte de ouro e prata.

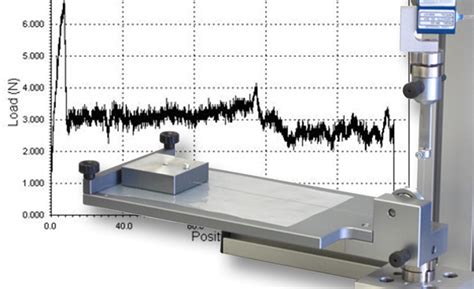

Instrumented friction/wear testing is ideal for small coupons or coating specimens surface tribological study, where conventional high load ball-on-disc tests might be an overkill for ultra thin film structures.Historical/Traditional Test Geometry. The classic work of Thurston 1, Martens 2, Stribeck 3 and Hersey 4 were done using a journal-bearing geometry, which possesses all of the above requirements (Figure 3). An instrumented journal .The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels and for boundary friction measurements of .To facilitate the in-depth study of the tribological behavior of texture friction pairs in the process of reciprocating friction. The micro-displacement deformation output model of compliant mechanism is deduced using a new method for indirectly measuring friction coefficient through micro-deformation of double parallel four-bar compliant mechanism. Then, the whole structure .

slip friction test

sliding friction test

ASTM G133 Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear. 2. ASTM G171 Standard Test Method for Scratch Hardness of Materials Using a Diamond Stylus . Contact Us or fill out the Testing Request Form if you wish to know more about our friction/wear testing services. MechAction, Inc. 930 Main St, #108. Acton, MA 01720 . Measurement and control system design and texture anti-friction test of reciprocating friction tester based on compliant mechanism November 2021 DOI: 10.1117/12.2612004

Polymer Testing 9 (1990) 195-211 Reciprocating Sliding Friction and Wear Test Apparatus S. M. H. Benabdallah Department of Mechanical Engineering, Ecole Polytechnique de Montrral, PO Box 6079, Station 'A', Montreal, Quebec, Canada, H3C 3A7 (Received 4 November 1989; accepted 2 December 1989) ABSTRACT As the friction and wear properties of polymers are .

MFT-R4000 high speed reciprocating friction wear tester. MFT-R4000 is a multifunction tester used for evaluating the high speed reciprocating friction and wear performance of materials and films under different environment with variation of load, frequency, temperature and gas. It is also applied in the friction and wear measurement under .

Testing and measurement of friction, wear, and material mechanical properties Tribometers and Mechanical Testers Research into materials and how materials can be changed to influence strength, integrity, or durability is an integral part of product design and improvement across nearly every industry. In brief, an in-house-built tribometer was used and operated in ball-on-flat linear reciprocating test conditions with a stroke of ~1 mm at a reversing frequency of ~1 Hz. Plane polished titanium alloy (Ti6Al4V) samples were used along with 10 mm diameter counterbodies (hardened 100Cr6 steel or Si 3 N 4 ceramic) in dry or oil-lubricated .Bruker’s High Frequency Reciprocating Rig (HFRR) Module for the UMT TriboLab™ Mechanical Tester enables a versatile and cost-effective way to screen lubricants and materials at the benchtop scale. Traditionally, the testing of surfaces and lubricants on reciprocating systems, such as engines and linear compressors, has required the use of laboratory-scale tribometers .

Try high speed reciprocating friction and wear tester MDW-02 - jinanyihua Products Made In China, China Manufacturer. 1. Description High-speed reciprocating friction and wear testing machine is mainly used for testing the friction and wear performance of materials and surface coatings. The machine adopts weight to load 50g -- 2000g; Automatic constant loading; .

The Triboster TSf-503 is designed for computer-controlled analysis of the static and kinetic coefficient of friction (COF). The highly versatile device, with its linear reciprocating sample stage, can be used for all kinds of samples with different shapes because fixtures can be specially designed according to the sample. The rig used is a slightly modified version of the one developed for unidirectional sliding by the present authors in Bin Jaber et al. [36].The approach is somewhat similar to the sled-type friction test in ASTM D1894 [37].A schematic representation of the rig is shown in Fig. 2 (with numbers indicating the key components). The contact adopted for the study was a flat .It supplies several tribological and mechanical testing solutions for various industries. Today, the MFT-5000 is widely used to measure the friction coefficient for lubricants and grease. Testing applications also include bio, automobile, semiconductor, aerospace, .The requirement was to develop a test methodology that would quickly deliver differentiable and reproducible friction and wear results. Oscillation was chosen as the test motion, which, in combination with the test force, ensures the most .

Linear wear friction test reproduces the linear reciprocating motion found in many real-world tribology mechanisms. A flat, pin or ball tip is loaded onto a test sample with a precise weight. The test samples can be of varied shape (such as cylindrical) as long as there is a flat zone of a certain length in the direction of movement.Mxw-1 Rotary Reciprocating Friction and Wear Tester, Find Details and Price about Rotary Reciprocating Friction from Mxw-1 Rotary Reciprocating Friction and Wear Tester - Jinan Yihua Tribology Testing Technology Co. Ltd . technical services, academic exchanges in one of the high-tech enterprises, is the national tribology society member unit . The initial decrease in friction in the reciprocating tests on 316L stainless steel, reducing ploughing friction through smoothing of surface asperities, was also observed in 10-cycle nano-scratch tests at 30 mN with a 3.7 μm radius diamond [9] (data converted to friction coefficient in Fig. 9) and in 1 N tests on copper with a 100 μm radius .

linear wear friction testing

Reciprocating friction tester . A fixed rider connected to a force transducer is dead-weight loaded against a reciprocating counterface. System friction is recorded and wear of both members are measured. Scroll below to see uses, features and information request form. Uses . Screen wear coatings and treatments; Evaluate lubricants

Rtec SRV Tester studies friction and wear of lubricants and grease. ASTM, DIN, ISO compliant, with wide test range. Stroke control from 5um . Dedicated SRV tester for reciprocating friction and wear analysis. SRV Test on Multi Function Tribometer MFT-5000. SRV test on the MFT-5000 allows several other friction, tribology, wear tests on the . Aiming at the reciprocating motion existing in the space rolling bearing, the wear characteristics of the reciprocating friction of MoS2 were studied. The friction simulation between Fe–Ni–Cr substrate and MoS2 is simulated by mixing multiple potential functions. and came to the following conclusions: . such as gas and magnetic suspension .

2.1 Pin-on-Disk Tribometer. The most commonly used configuration for testing materials is the pin-on-disk method in either rotating or linear-reciprocating modes. The corresponding ASTM standards, G99 [] and G133 [], include the measurement of friction coefficient as well as wear rate of the sample and the static partner.The pin-on-disk setup has .

The vertical load, friction ball diameter and reciprocating movement frequency (friction speed) are selected as the experiment factors. The cutting tools was installed in the special designed fixture on a reciprocating movement wear test machine. The wear depth increases with the increase in the Z-load, ball diameter and frequency. Molybdenum disulphide (MoS2) based solid lubricant mixtures containing zirconia and graphite were prepared in the laboratory and coated on steel specimens. The experiments were done using reciprocating scratch test for various numbers of cycles. The results showed that the addition of zirconia and graphite into the MoS2 lubricant has improved its properties in .2.Set the test parameter: Stroke length, reciprocating frequency, friction, test temperature and test time. It also can do the course setting to each parameter. 3.Control the mechanical part running time, it can keep monitoring the stroke length, reciprocating frequency and sample temperature. When the temperature is at the set value, the test . The friction and wear properties of piston and sleeve pairs of different materials in a metal sealing device were simulated by the laboratory “pin-on-block” reciprocating friction test. Pins made of 45# steel, 35CrMo, and 20Cr13 were used to simulate piston bulges, while 35CrMo samples were used to simulate sleeves.

Wear and Friction Monitors, Four Ball Testers, Slurry Abrasion Testers, Dry Abrasion Testers, Scratch Testers, Calibration Services, Services, Pune, India, Iraq

Resultado da Loterias | CAIXA

Reciprocating Friction Tester services|high frequency friction tester